A screw conveyor, or auger conveyor, is used to transporting liquid or granular materials. It typically encloses a spinning helical screw blade flighting in a tube. Numerous bulk-handling sectors employ them. Sometimes the conveyor’s rotating component is referred to as a drill. Read More…

We are a US based, family owned company specializing in the design and manufacturing of screw conveyors in all configurations: vertical, inclined, shaftless, live bottom, plug screws, feeders, mixers, heating/cooling, FDA/USDA approved, screw presses and more.

Automated Flexible Conveyor (AFC) designs and manufactures the SPIRALFEEDER(TM) flexible screw conveyors to automatically transfer, load, weigh, and unload powders, pellets, granules, mixtures, and other dry, bulk materials fast, gently, and safely. Expert engineers offer decades of experience in designing the ideal custom screw conveyor for your bulk material handling application. Try your...

ISC Manufacturing LLC has specialized in screw conveyor manufacturing since 1976. Experts in the field of CNC machining, ISC designs & manufactures custom feeders, mixing & drag conveyors, bucket elevators, ribbon & paddle mixers, chutes & more. Our screw conveyor technology is such that our conveyors are capable of conveying, feeding, elevating & mixing. Ask about our service repair center!

At Akona Process Solutions, we take pride in engineering screw conveyors that provide reliable and efficient material handling for a wide range of industries. We design our conveyors to move bulk materials with precision, ensuring smooth and consistent flow whether the application involves powders, granules, or heavier solids.

At ProcessBarron, we specialize in delivering engineered material handling solutions that keep industrial operations moving efficiently and reliably. Our expertise in screw conveyors allows us to design and manufacture equipment that handles a wide range of bulk materials with precision and durability.

At Screw Conveyor Parts, LLC, we take pride in being a trusted resource for everything related to screw conveyors. We offer a comprehensive selection of screw conveyor components and systems designed to meet the demands of a wide range of industries, including agriculture, food processing, wastewater treatment, and manufacturing.

More Auger Conveyor Manufacturers

Auger Conveyors: Comprehensive Guide, Types, Applications, and Selection Tips

Auger conveyors, also known as screw conveyors, are among the most versatile and cost-effective material handling solutions in modern industry. Leveraging a helical screw blade, or “flight,” these conveyors efficiently transport a wide range of semi-solid and bulk materials, including powders, granules, grains, sludges, and viscous substances. Predominantly used in manufacturing, processing, and production environments, auger conveyors can be installed horizontally, at a slight downward angle, or at an incline, depending on the specific application requirements. Whether you need to elevate, move, dose, or homogenize materials, auger conveyors offer precision, adaptability, and reliability.

What Is an Auger Conveyor?

An auger conveyor utilizes a rotating helical screw blade to move bulk materials along a trough or enclosed tube. This mechanical conveying system is ideal for controlled, continuous movement of products—ranging from free-flowing powders to semi-solid slurries—in industrial, agricultural, food processing, chemical, and wastewater treatment settings. The screw or auger is typically powered by a motor and is designed to optimize throughput while minimizing maintenance and operational costs. Auger conveyors are prized for their ability to transport materials in a fully enclosed environment, which helps reduce dust, contamination, and material loss.

Types of Auger Conveyors

When considering an auger conveyor system, understanding the different available types is crucial for selecting the best solution for your material handling needs. Each design offers unique advantages tailored to specific use cases, materials, and operating conditions.

Horizontal Screw Conveyors

The most common and straightforward configuration, horizontal screw conveyors are used for transporting bulk materials efficiently over relatively short distances. These systems are compatible with a wide range of material properties, from fine powders to granular substances, and are often chosen for their reliability and simplicity. With the option for multiple inlets and discharge points, horizontal screw conveyors excel in distributing materials to different areas within a facility, enhancing process flexibility.

Unlike belt conveyors, horizontal auger conveyors are an affordable alternative that offers enclosed or open designs to suit sanitary or inspection needs. They are frequently used for mixing and homogenizing materials during transport, making them ideal for food processing, chemical blending, grain handling, and pharmaceuticals.

- Ideal for: Free-flowing powders, grains, pellets, and dry bulk materials

- Industries: Agriculture, food production, plastics, chemicals, and minerals

- Advantages: Cost-effective, minimal spillage, customizable inlets/outlets

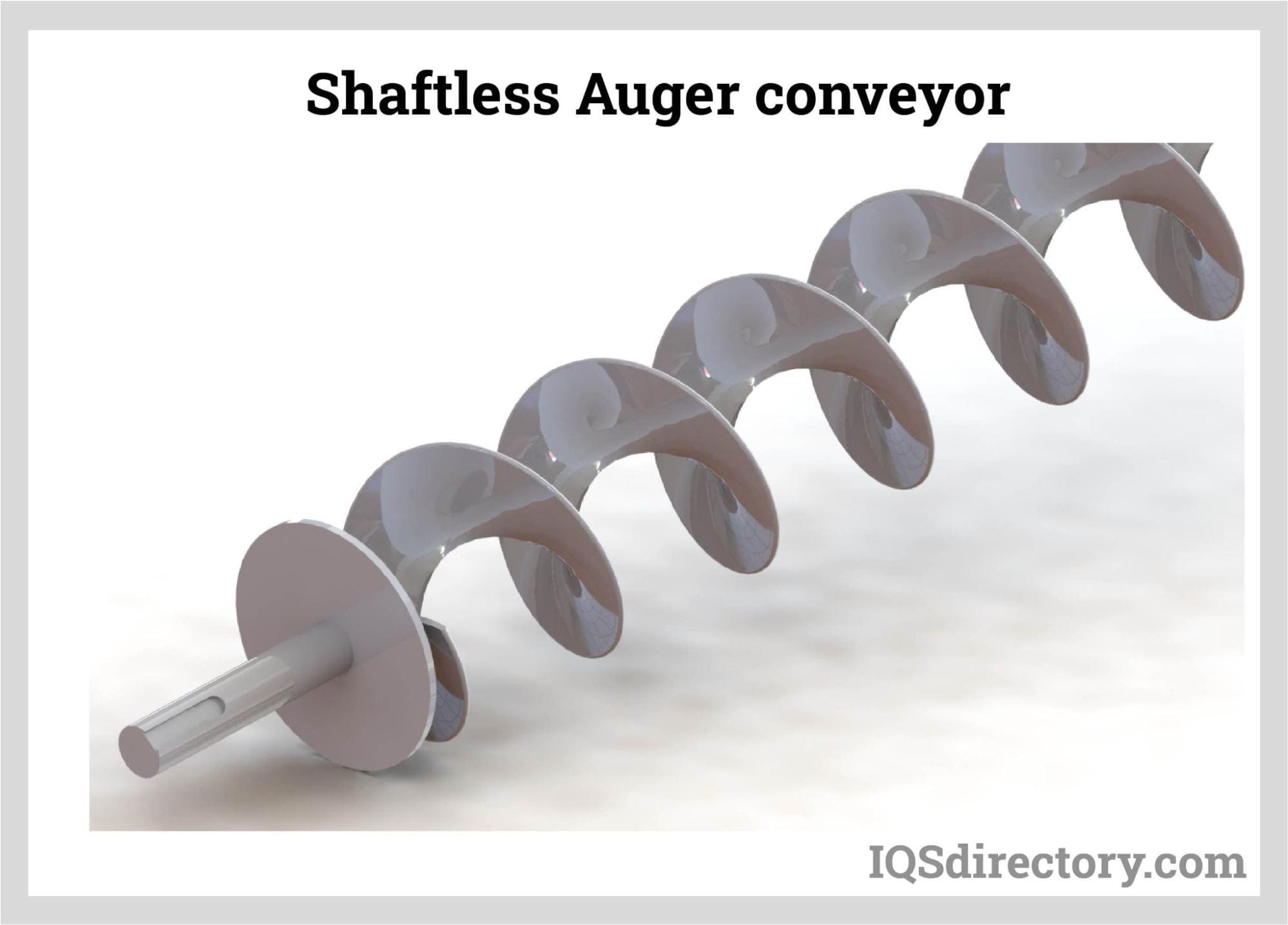

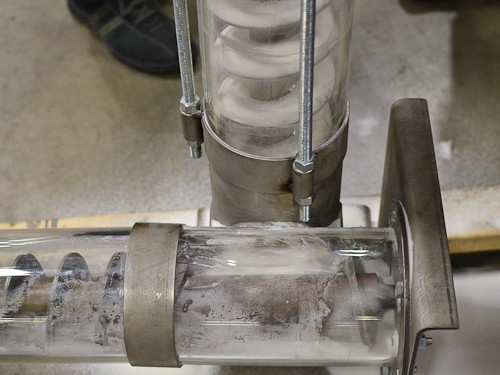

Shaftless Auger Conveyor

The shaftless auger conveyor, also known as a ribbon screw conveyor, features a helical screw without a central shaft. This design innovation enables the conveyor to move challenging materials that tend to clog or stick in traditional screw conveyors. The open spiral allows for greater flexibility, higher fill rates, and lower rotational speeds, reducing wear and maintenance requirements.

Shaftless screw conveyors are ideally suited for handling sticky, stringy, viscous, or irregular materials that are difficult to convey with conventional systems. These conveyors are particularly valuable in industries such as wastewater treatment, mining, and food processing, where the conveyed material may include sludges, screenings, or other problematic solids.

By eliminating the central shaft, shaftless spiral conveyors prevent material buildup and blockages, ensuring consistent flow and operational uptime. They can be fabricated from various materials—including stainless steel, carbon steel, and specialty alloys—to meet specific corrosion, abrasion, or sanitary requirements.

- Ideal for: Dewatered sludge, industrial waste, bio-solids, food waste, and fibrous materials

- Industries: Wastewater treatment, food production, chemical processing, mining

- Advantages: Non-clogging, higher efficiency, lower downtime, minimal maintenance

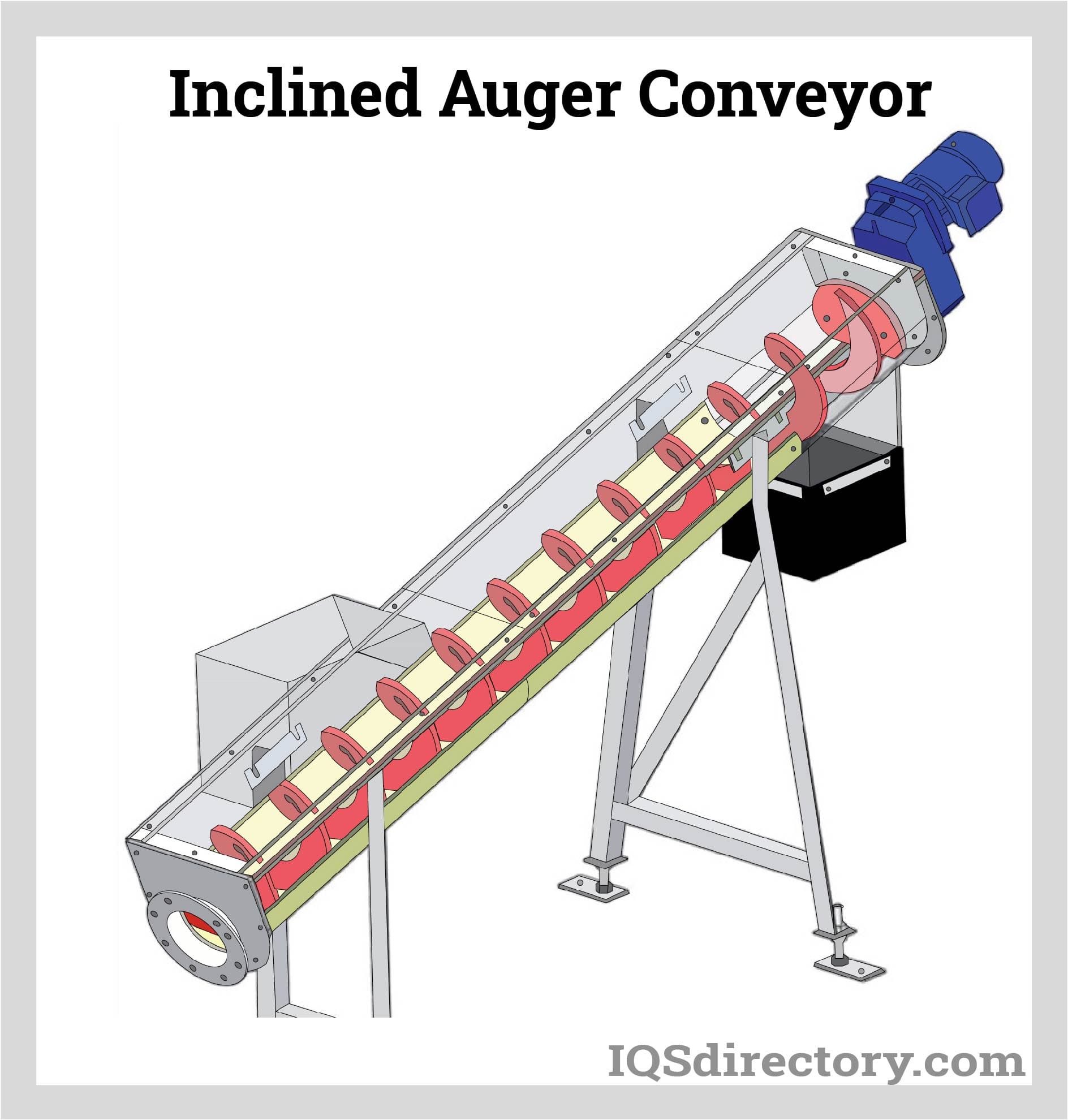

Inclined Auger Conveyor

Inclined screw conveyors are engineered to move materials upward at an angle, typically between 0 and 45 degrees. As the angle of inclination increases, the conveyor’s capacity decreases and the power requirements rise due to gravity and material fallback. To optimize performance, manufacturers often use reduced-pitch screws and tubular troughs, which help minimize product rollback and maximize conveying volume.

Inclined auger conveyors are essential for transferring materials to elevated locations, such as hoppers, silos, or next-stage processing equipment. They are commonly used in the food, chemical, plastics, and construction industries—where space constraints or process requirements necessitate vertical or inclined movement.

- Ideal for: Elevating bulk materials, feeding mixers, transferring products between floors

- Industries: Food processing, agriculture, plastics, cement, pharmaceuticals

- Considerations: Increased torque, careful design to reduce material fallback

Vertical Auger Conveyors

For maximum elevation in limited footprints, vertical screw conveyors transport materials straight up. These systems are ideal for transferring powders, granules, and small particles from ground-level hoppers into tall silos, mixers, or reactors. Their compact design makes them invaluable in busy processing plants with space limitations.

- Ideal for: Vertical elevation of powders, grains, pellets, and granular materials

- Industries: Food and beverage, plastics, cement, chemical, and feed mills

- Benefits: Space-saving, efficient vertical movement, minimal dust emission

Flexible Screw Conveyors

Flexible auger conveyors use a flexible, rotating helical screw inside a flexible tube to convey materials around corners and obstacles. These systems are perfect for installations requiring intricate routing or where process equipment is not aligned. Flex screw conveyors are commonly used for conveying free-flowing to semi-free-flowing powders and small granules.

- Ideal for: Powders, granules, flakes, and small pellets

- Industries: Food, pharmaceuticals, plastics, and chemicals

- Advantages: Easy installation, versatile routing, gentle material handling

Common Applications of Auger Conveyors

Auger conveyors are used across a broad range of industries to streamline the transportation, dosing, mixing, and elevation of materials. Here are some of the most prominent applications:

- Agriculture: Moving grains, seeds, and animal feeds in silos, bins, and hoppers; transferring crop from harvesters to storage.

- Food Processing: Conveying flour, sugar, spices, and other ingredients; feeding mixers, extruders, and packaging machines.

- Wastewater Treatment: Removing dewatered sludge, screenings, and grit from processing tanks.

- Mining & Minerals: Handling ores, coal, and mining waste products efficiently and safely.

- Construction: Transferring cement, sand, lime, and aggregates on job sites and in batching plants.

- Chemical Processing: Moving powders, granules, and hazardous materials in controlled environments.

- Plastics: Feeding plastic pellets, powders, and regrind into extruders and molding machines.

- Pellet Stoves & Grills: Moving fuel pellets from storage hoppers to burners for automated feed control.

- Snow Removal: Snowblowers use augers to move snow into impellers for discharge.

- Garbage Compactors: Pushing waste into compacting plates for efficient disposal.

- Ice Resurfacing: Augers collect and move ice shavings during rink resurfacing.

What problems can an auger conveyor solve in your operation?

Are you facing challenges with material flow, dust control, or space constraints? Auger conveyors provide solutions by offering enclosed, dust-tight conveying, customizable layouts, and the ability to handle difficult or hazardous materials. Their versatility makes them integral to improving efficiency, safety, and product consistency in modern manufacturing and processing facilities.

Key Benefits of Auger Conveyors

- Versatility: Transport a wide variety of materials—dry, wet, sticky, abrasive, or fragile—by selecting the right screw type and material of construction.

- Hygienic and Safe: Enclosed designs prevent contamination, reduce dust emissions, and protect workers from exposure to hazardous materials.

- Space-Efficient: Compact designs fit into tight spaces and can be tailored for complex plant layouts with multiple inlets and outlets.

- Customizable: Configurable lengths, diameters, materials, and drive options allow for precise adaptation to your needs.

- Low Maintenance: Fewer moving parts, enclosed operation, and easy access for cleaning and inspection reduce downtime and maintenance costs.

- Energy Efficient: Optimized design means lower energy consumption compared to pneumatic conveyors for similar capacities.

- Material Mixing: Screw conveyors can homogenize, blend, or break up lumps during transport, improving product quality.

- Controlled Discharge: Accurate metering and dosing are possible, making auger conveyors ideal for batch and continuous processing.

- Thermal Processing: Optional jacketed or hollow-flight screws allow for heating, cooling, or drying of materials during transport.

- Environmental Control: Maintain internal pressure and vapor containment—crucial for handling volatile, toxic, or odorous products.

- Integration: Compatible with hoppers, mixers, packaging lines, and automated systems for seamless material flow.

How do auger conveyors compare to belt, pneumatic, or drag conveyors?

While belt conveyors are excellent for bulk, non-dusty materials, auger conveyors outperform in enclosed, dust-tight applications or when handling sticky or hazardous materials. Pneumatic conveyors offer fast, long-distance transfer but require more energy and are less suitable for abrasive or fragile products. Drag conveyors are used for heavy, abrasive applications but are less flexible in plant layout. Auger conveyors fill the gap for controlled, enclosed, and versatile material handling at a competitive cost.

Choosing the Right Auger Conveyor for Your Business

Selecting the optimal auger conveyor system is critical for maximizing efficiency, safety, and ROI in your operation. Here are key decision factors to consider:

- Material Characteristics: Particle size, abrasiveness, stickiness, moisture content, and temperature requirements all influence screw design and material selection.

- Capacity Requirements: Determine throughput in tons/hour or cubic feet/minute to size the conveyor appropriately.

- Conveyor Length and Layout: Assess plant space, required routing, and whether horizontal, inclined, vertical, or flexible configurations are needed.

- Environment: Consider exposure to chemicals, moisture, dust, or temperature extremes to select proper materials and finishes.

- Sanitation: For food or pharmaceutical applications, opt for easy-clean designs, FDA-approved materials, and sanitary construction.

- Integration: Ensure compatibility with upstream and downstream equipment, including hoppers, feeders, mixers, or packaging systems.

- Maintenance Access: Look for designs with removable covers, easy-access inspection ports, and minimal moving parts.

- Budget: Balance upfront investment with long-term maintenance, energy costs, and operational flexibility.

- Safety Features: Evaluate guarding, emergency stops, and dust/vapor containment as needed for safe operation.

Ready to compare auger conveyor manufacturers and get a quote?

Visit our directory of auger conveyor companies to request information, compare capabilities, and connect directly with industry-leading manufacturers. Each profile offers detailed areas of expertise, technical resources, and a simple RFQ form to streamline your purchasing process. Not sure which supplier fits your needs? Use our patented website previewer to evaluate and shortlist the best options before making a decision.

Frequently Asked Questions About Auger Conveyors

- How do I determine the right screw diameter and pitch for my material?

Consult with manufacturers or use online calculators to match material characteristics and required capacity with the appropriate screw dimensions and speed. - Which industries benefit most from auger conveyors?

Key industries include food and beverage, agriculture, chemicals, pharmaceuticals, wastewater treatment, plastics, and mining. - Can auger conveyors handle abrasive or corrosive materials?

Yes—by selecting appropriate screw and trough materials such as hardened steel, stainless steel, or specialty coatings. - Are there sanitary auger conveyors for food and pharma?

Absolutely. Hygienic designs with quick-disassembly, polished surfaces, and FDA-grade materials are available. - How do I maintain and clean an auger conveyor?

Choose systems with removable covers, clean-out ports, and tool-free access for fast, regular cleaning and inspection. - What is the typical lifespan of an auger conveyor?

With proper selection, installation, and maintenance, auger conveyors often operate reliably for 10-20+ years. - Do auger conveyors support automation and IoT integration?

Many modern systems offer sensors, variable speed drives, and PLC integration for automated, data-driven operations. - What are the delivery times for custom auger conveyor systems?

Lead times vary by complexity and manufacturer, but most standard solutions are available within 6-12 weeks from order.

Auger Conveyor Accessories and Customization Options

To further optimize your auger conveyor system, consider a range of accessories and customizations that can enhance performance, safety, and ease of use:

- Feed Hoppers: For controlled loading of bulk materials into the conveyor.

- Variable Speed Drives: To adjust conveying rates for different products or processing steps.

- Level Sensors and Controls: For automated material flow and integrated process control.

- Jacketed Troughs: Enable heating or cooling of materials during transport.

- Inspection Ports and Access Doors: Simplify maintenance and cleaning.

- Custom Screw Designs: Multiple flight configurations (e.g., ribbon, cut-and-fold, paddle) for specific material behaviors.

- Enclosures and Seals: Ensure dust-tight, vapor-tight, or explosion-proof operation as needed.

- Discharge Gates and Valves: For precise flow control and batch operation.

Ask your supplier about the most effective accessories and upgrades for your application to maximize ROI and operational reliability.

Conclusion: Why Choose an Auger Conveyor?

Auger conveyors are a proven, cost-efficient, and highly adaptable solution for bulk material handling across countless industries. With a range of configurations—including horizontal, inclined, vertical, shaftless, and flexible designs—they easily integrate with modern processing and production lines. Their enclosed operation minimizes dust and contamination, while customizable features and accessories address even the most demanding requirements. Whether you’re scaling up production, improving plant hygiene, or optimizing process flow, choosing the right auger conveyor can deliver significant gains in efficiency, safety, and product quality.

Need expert advice or a custom quote?

Explore our comprehensive auger conveyor manufacturer directory and take the next step towards a more efficient, reliable, and future-proof material handling system. Request a quote, compare suppliers, and discover the ideal solution for your specific needs today!

Bulk Bag Handling

Bulk Bag Handling Industrial Dryers

Industrial Dryers Mixers & Blenders

Mixers & Blenders Palletizers

Palletizers Pneumatic Conveyors

Pneumatic Conveyors Screw Conveyors

Screw Conveyors Vibratory Feeders

Vibratory Feeders Weighing Systems & Scales

Weighing Systems & Scales Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services