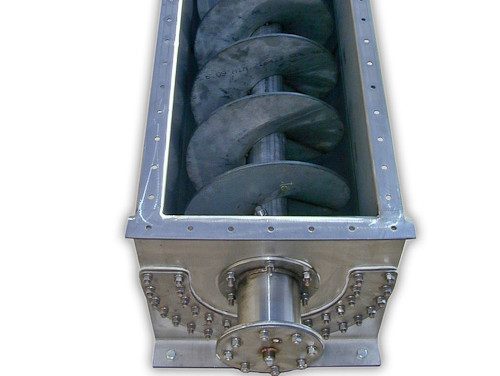

Screw conveyors, also known as auger conveyors or industrial screw conveyors, are systems designed to transfer free-flowing and non-free-flowing, dry and semi-dry bulk materials. Note: Since the operation of the system involves a screw cutting through the bulk materials, we do not recommend using screw conveyors to process substances that are sticky or do not break down easily, such as gels. Read More…

We are a US based, family owned company specializing in the design and manufacturing of screw conveyors in all configurations: vertical, inclined, shaftless, live bottom, plug screws, feeders, mixers, heating/cooling, FDA/USDA approved, screw presses and more.

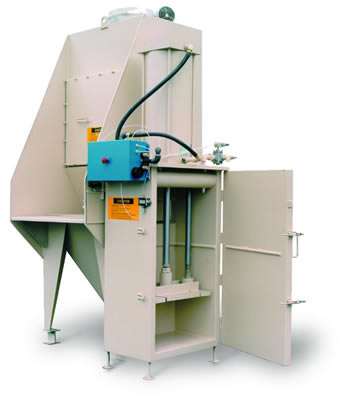

VAC-U-MAX is a manufacturer specializing in screw conveyors and transportation systems, load filling machines, bulk bag loaders, grinders, pulverizers and sifters. The company serves the chemical, food and feedmill industries with highly efficient products.

ISC Manufacturing LLC has specialized in screw conveyor manufacturing since 1976. Experts in the field of CNC machining, ISC designs & manufactures custom feeders, mixing & drag conveyors, bucket elevators, ribbon & paddle mixers, chutes & more. Our screw conveyor technology is such that our conveyors are capable of conveying, feeding, elevating & mixing. Ask about our service repair center!

Spiroflow Systems has more than 40 years of experience in the design, manufacture & installation of bulk material handling equipment & systems. Product innovation & a thorough understanding of customers’ needs & objectives keep Spiroflow at the forefront of the industry. Spiroflow Systems offers flexible screw, aero mechanical, pneumatic, tubular cable & chain drag conveyors as well as bulk...

For over 40 years, CDM’s mission has been to use our excellent application knowledge and customer service to provide our clients with superior solutions. We have grown to become a world leader in the manufacturing of conveying systems, conveyor chains, and material handling equipment. Industries we serve include minerals and mining, pulp and paper, and potash and fertilizer. Contact us today...

At Syntron Material Handling, we pride ourselves on our innovative screw machine products that redefine efficiency and reliability in material handling solutions. With years of expertise and dedication to excellence, we offer a comprehensive range of screw machines designed to meet the diverse needs of industries worldwide.

More Screw Conveyor Manufacturers

Applications

Screw conveyors are designed to efficiently transport items like packages, equipment, food, or products from one location to another. They are particularly useful for automated or semi-automated finishing and manufacturing processes. These conveyors excel at moving dry, loose materials between various locations, including pits, trucks, barrels, rail cars, silos, hoppers, and vats.

As a result, screw conveyors find applications across diverse industries, including construction, oil and gas, mining, chemical, pharmaceutical, plastics, food processing, and agriculture.

In farming and agriculture, screw conveyors play a crucial role within machinery such as balers or threshers, aiding in the movement of grains and animal feed to different destinations. Within food processing, these conveyors are essential for transporting dry ingredients like nuts, salt, and flour, crucial in the production of various food items. In the construction industry, industrial screw conveyors are employed to blend wet and dry components, facilitating the creation of materials like plaster or cement.

History

The history of screw conveyors traces back to the 3rd century BC, when the ancient Greek scientist and mathematician Archimedes invented what became known as Archimedes’ screw or screw pump. However, it is believed by many historians that Archimedes drew inspiration for his auger conveying system from his visits to Egypt, among other regions in the Ancient Near East where similar screw conveying systems likely existed. Assyrian cuneiform tablets indicate that during the reign of King Sennacherib (704-681 BC), engineers crafted bronze water screws. Additionally, the classical Greek historian Strabo mentioned the use of screws for irrigation in the Hanging Gardens of Babylon.

Archimedes’ auger conveyor system introduced this mechanism to the Western world. It consisted of a hollow cylinder with a shaft and a spiral attached to both the shaft and the inner wall of the cylinder. This innovation enabled more efficient irrigation, drainage of land, and water removal for ships.

In 1405, Konrad Kyeser, a German military engineer, detailed in his book Bellifortis an Archimedes screw enhanced with a crank mechanism. This innovation swiftly supplanted the traditional screw systems of its time.

Engineers developed the modern screw conveyor system between the late 19th and mid-20th centuries. During that era in the USA, screw conveyors gained popularity in agriculture, particularly for processing feed and grain. Even today, many farmers continue to use them, often referring to them as grain conveyors. In the early stages of modernization, screw conveyors played a crucial role in feed mills across the US. As commercial food production expanded, these conveyors began transporting perishable food ingredients. Additionally, they found widespread application in construction, where they remain indispensable for conveying materials such as cement.

During the 1900s, engineers and manufacturers continuously enhanced and innovated materials used in equipment such as auger conveyors. A standout advancement during this period was stainless steel, known for its durability and corrosion resistance. These improvements, coupled with technological advancements, revolutionized screw conveyors. In modern times, auger conveying systems exemplify automation and robotics integration. This evolution significantly boosts efficiency and elevates quality standards. Moreover, manufacturers now deploy auger conveyors across a broad spectrum of applications, ranging from light-duty tasks to exceedingly demanding operations.

How It Works

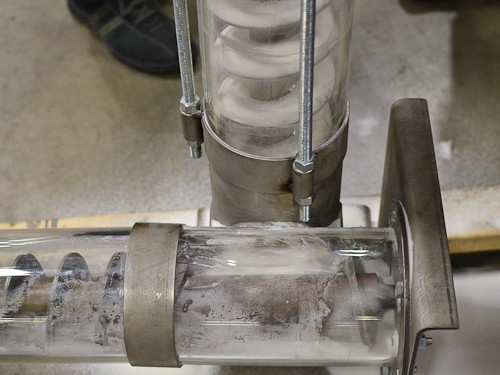

Screw conveyors function by rotating bulk materials between different points, leveraging Archimedes’ screw principle. This principle asserts that when a helical screw or auger is properly positioned within a tube or cylinder, it can efficiently transport materials in a designated direction. Furthermore, with each rotation, the screw facilitates the continuous entry of new materials into the tube.

They transport materials at a set flow rate, which can be measured in cubic feet per hour, pounds per hour, or tons per hour, depending on the specific application. They derive power from electricity, gravity, or another machine’s energy.

Types

Conveyor systems consist of various types of conveying augers combined together.

Belt conveyors stand as the predominant type of conveyor, utilizing a broad rubber or polymer belt that circulates thanks to a minimum of two uni-directional pulleys. These belts wrap around the pulleys. Their versatility makes them indispensable across various industries, ranging from aerospace to retail.

Chain conveyors are a type of screw conveyor equipped with a chain drive as its primary driving mechanism. This chain drive serves not only to transmit power but also allows operators to adjust speed by varying the gear ratio. Chain conveyors excel in handling abrasive, fragile, and/or dry materials efficiently.

Roller conveyors utilize round rotating elements called rollers, situated on a flat surface to transport loads. They operate through either gravity or electric motor propulsion and find extensive application across sorting, washing, drying, finishing, and shipping tasks.

Spiral conveyors encompass any screw conveyor employing an enclosed spiral screw.

Overhead conveyors, contrary to typical conveyor systems, operate from above rather than below. Their tracks are typically supported by ceilings, walls, stands, or racks. These systems can be driven manually, by gravity, electricity, pneumatics, or vacuum. By utilizing overhead space, they liberate floor areas for other tasks and equipment, thereby reducing labor requirements.

Vertical conveyors transport materials directly upwards and downwards, utilizing tubular casings to contain the materials, thus classifying them as tubular screw conveyors. They are employed for transferring materials between receptacles with significant height disparities. Vertical conveyors offer lower maintenance requirements compared to bucket elevators and ensure continuous material transport.

Horizontal conveyors, also referred to as horizontal screw conveyors, move materials linearly along the ground. Because of this, they only need a trough. They find utility in various processes such as dewatering, compaction, aeration, heating and cooling, drying, and mixing.

Inclined conveyors tilt at an angle, demanding more space and power than their counterparts. However, they efficiently transport bulk materials between floors, offering economical movement. Some models are even portable, allowing for easy relocation from one area to another.

Gravity conveyors transport items utilizing gravitational force rather than motorized power. Included in this category are ball transfer and chute conveyors.

Tubular drag conveyors employ a chain drive featuring flights. This design enables them to draw materials through a sealed pipe circuit. Operating at high speeds with low torque, tubular conveyors accommodate varying capacities efficiently.

Pneumatic conveyors consist of tubular systems powered by air, designed primarily for transporting bulk solid powders.

Flexible screw conveyors bend in multiple directions and adapt their angles, contrasting with stationary traditional carbon steel conveyors. This versatility allows them to serve various purposes within a single facility.

Portable screw conveyors are designed for convenient mounting on vehicles, carts, or stands. They are typically purchased for the transportation of powdered or granulated materials.

Vibratory conveyors feature metal troughs that oscillate to propel materials unidirectionally. Typically handling bulk powders and mixtures such as gypsum, crushed cement, fertilizer, wood waste, food products, minerals, and glass, these conveyors utilize electromagnetic or electromechanical vibrators affixed at intervals along the trough’s base to generate vibrations.

Flowable materials are transported by bucket elevators equipped with buckets that can be affixed to either vertical or inclined conveyors.

Equipment Components

Typically, screw conveyors consist of these essential parts:

- A conveyor screw, alternatively referred to as a spiral blade or helicoid flighting

- A trough or tubular casing for the screw conveyor

- A drive unit, which includes a shaft coupling and shaft seal, or alternatively, a chain drive

- The drive mechanism itself

The spiral blade of the conveyor screw wraps around a shaft and resides within a tubular casing. It is powered at one end and secured at the other. The trough may include a cover or remain uncovered. Alternatively, shaftless screw conveyors omit the shaft, with the spiral blade driven at one end and unencumbered at the opposite end.

Benefits

Screw conveyors offer a multitude of advantages: they ensure gentle handling and effective mixing of materials, enhance system speed and efficiency, and boast both low initial costs and long-term durability. Among conveyor options, screw conveyors stand out for their affordability in both procurement and upkeep. Moreover, they are highly adaptable and customizable, proving endlessly versatile in handling a wide array of materials including lead oxide, whey, fiberglass, vitamins, Epsom salts, garlic powder, flour, cocoa beans, ferric sulfate, gypsum, caffeine powder, and carbon black.

Design and Customization

Materials

Most screw conveyors come in metal, though some are crafted from injection-molded thermoplastic resin. Those made from resin excel in withstanding high temperatures and impacts while ensuring material purity. Among metals, stainless steel, often food grade, reigns supreme in industrial screw conveyors construction for its non-contaminating nature and sleek surface.

Considerations

When manufacturers design or recommend a screw conveyor, they must take into account several factors: the specific application, characteristics of the material to be transported (such as consistency, density, flowability, size, corrosiveness, texture, and flammability), the volume of material to be moved, expected frequency of use, and any additional processes the conveyor needs to perform. These details guide decisions on system materials, orientation, accessories, and power source options—whether powered by an electric motor or by energy from adjacent machines.

To cater perfectly to your requirements, manufacturers of screw conveyors offer a variety of customization options. These include adding sections or attachments such as wash-down sections, mobile base units, flexible discharge hoses, integral bag dump hoppers, access and inspection ports, and even crafting portable screw conveyors.

Safety and Compliance Standards

In the United States, it’s advisable to opt for a CEMA-certified conveyor. CEMA, known as the Conveyor Equipment Manufacturers Association, establishes guidelines and standards ensuring the fabrication of safe, efficient, and well-designed conveyor systems.

Additionally, your conveyor should be certified to meet the specific standards required for your application or industry. For instance, a conveyor used in food processing must adhere to FDA standards, while a grain conveyor should comply with USDA regulations. For more details, consult with industry experts.

How to Find the Right Manufacturer

To find the ideal screw conveyor for your needs, it’s crucial to partner with the best manufacturer. Remember, the right manufacturer isn’t necessarily the cheapest option, but the one who can tailor a conveyor to meet your exact specifications, standards, timeline, and budget. Choosing wisely ensures you won’t compromise on quality to save costs. A reputable manufacturer will collaborate with you respectfully throughout the process. Explore the detailed options listed on this page to discover a screw conveyor manufacturer that fits this description. Best of luck in your search!

Bulk Bag Handling

Bulk Bag Handling Industrial Dryers

Industrial Dryers Mixers & Blenders

Mixers & Blenders Palletizers

Palletizers Pneumatic Conveyors

Pneumatic Conveyors Screw Conveyors

Screw Conveyors Vibratory Feeders

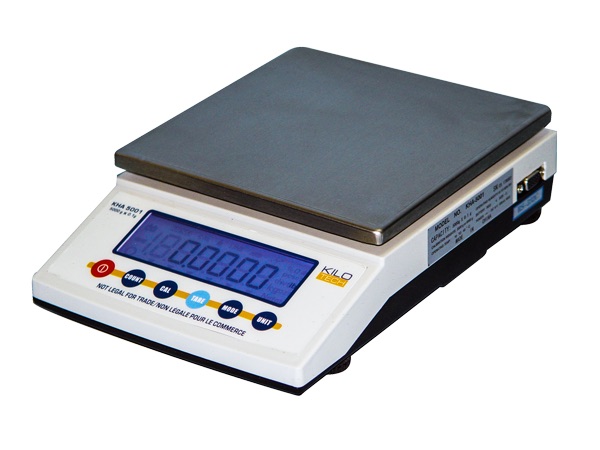

Vibratory Feeders Weighing Systems & Scales

Weighing Systems & Scales Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services