Inclined screw conveyors are used in a few different applications within the process industry. These applications include the agricultural, construction and food and beverage industries. They transport raw materials like cement, fertilizer, feed, sugar and meat. Read More…

We are a US based, family owned company specializing in the design and manufacturing of screw conveyors in all configurations: vertical, inclined, shaftless, live bottom, plug screws, feeders, mixers, heating/cooling, FDA/USDA approved, screw presses and more.

VAC-U-MAX is a manufacturer specializing in screw conveyors and transportation systems, load filling machines, bulk bag loaders, grinders, pulverizers and sifters. The company serves the chemical, food and feedmill industries with highly efficient products.

ISC Manufacturing LLC has specialized in screw conveyor manufacturing since 1976. Experts in the field of CNC machining, ISC designs & manufactures custom feeders, mixing & drag conveyors, bucket elevators, ribbon & paddle mixers, chutes & more. Our screw conveyor technology is such that our conveyors are capable of conveying, feeding, elevating & mixing. Ask about our service repair center!

Spiroflow Systems has more than 40 years of experience in the design, manufacture & installation of bulk material handling equipment & systems. Product innovation & a thorough understanding of customers’ needs & objectives keep Spiroflow at the forefront of the industry. Spiroflow Systems offers flexible screw, aero mechanical, pneumatic, tubular cable & chain drag conveyors as well as bulk...

For over 40 years, CDM’s mission has been to use our excellent application knowledge and customer service to provide our clients with superior solutions. We have grown to become a world leader in the manufacturing of conveying systems, conveyor chains, and material handling equipment. Industries we serve include minerals and mining, pulp and paper, and potash and fertilizer. Contact us today...

At Syntron Material Handling, we pride ourselves on our innovative screw machine products that redefine efficiency and reliability in material handling solutions. With years of expertise and dedication to excellence, we offer a comprehensive range of screw machines designed to meet the diverse needs of industries worldwide.

More Inclined Screw Conveyor Manufacturers

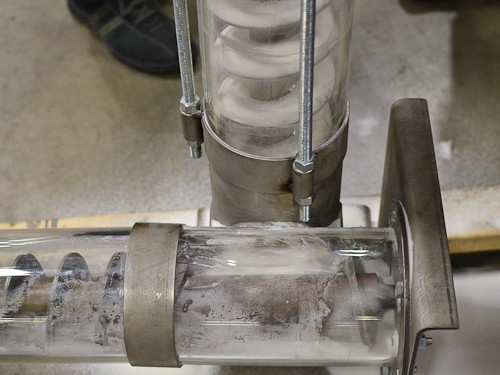

Commonly seen in the food industry, these conveyors transport ingredients to and from mixers, ovens and vats and need to be sterile at all times. Therefore, they are commonly made of stainless steel, a smooth food grade metal that is less likely to contaminate edible ingredients than other materials and is easily cleaned. Like all industrial screw conveyors, those that are inclined use a spiral, rotating screw within a trough that pushes loose material forward. Because of the incline, these conveyors are not able to transport liquid materials. Instead, they convey powders, solid food ingredients, loose mixtures and pastes.

The slope of an inclined screw conveyor determines the amount of material that it may hold at one time. As the angle increases and becomes steeper, the conveyor's capacity decreases. For example, a conveyor carrying material up a 15º angle is able to carry 75% of its horizontal capacity, while a conveyor operating at 25º holds only 50% of its horizontal capacity. Inclined conveyors should never have internal screw supports, as they obstruct the production flow.

Since the material tends to fall back because of gravity it must overcome, inclined screw conveyors use trough covers and tubular housings to keep the material from falling off or spilling. If necessary, inclined screw conveyors are able to stow away in a vertical position when they are not needed, which saves storage space. They are often attached to a vat, mixer, tank, silo or oven and are most often used when material is transported from a small container to a large one that is much higher up. Because of the constant rotation of the spiral screw, inclined screw conveyors may also perform some additional blending or homogenizing during transportation.

Bulk Bag Handling

Bulk Bag Handling Industrial Dryers

Industrial Dryers Mixers & Blenders

Mixers & Blenders Palletizers

Palletizers Pneumatic Conveyors

Pneumatic Conveyors Screw Conveyors

Screw Conveyors Vibratory Feeders

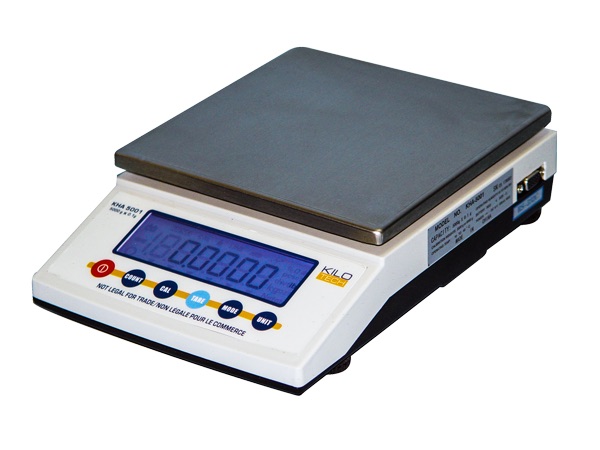

Vibratory Feeders Weighing Systems & Scales

Weighing Systems & Scales Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services