A screw conveyor, or auger conveyor, is used to transporting liquid or granular materials. It typically encloses a spinning helical screw blade flighting in a tube. Numerous bulk-handling sectors employ them. Sometimes the conveyor’s rotating component is referred to as a drill. Read More…

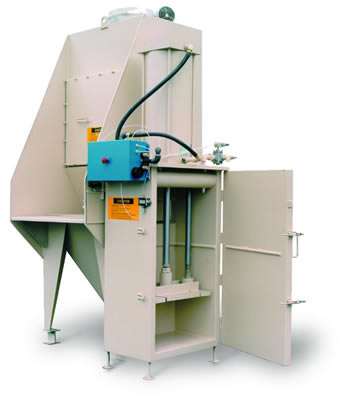

We are a US based, family owned company specializing in the design and manufacturing of screw conveyors in all configurations: vertical, inclined, shaftless, live bottom, plug screws, feeders, mixers, heating/cooling, FDA/USDA approved, screw presses and more.

VAC-U-MAX is a manufacturer specializing in screw conveyors and transportation systems, load filling machines, bulk bag loaders, grinders, pulverizers and sifters. The company serves the chemical, food and feedmill industries with highly efficient products.

ISC Manufacturing LLC has specialized in screw conveyor manufacturing since 1976. Experts in the field of CNC machining, ISC designs & manufactures custom feeders, mixing & drag conveyors, bucket elevators, ribbon & paddle mixers, chutes & more. Our screw conveyor technology is such that our conveyors are capable of conveying, feeding, elevating & mixing. Ask about our service repair center!

Spiroflow Systems has more than 40 years of experience in the design, manufacture & installation of bulk material handling equipment & systems. Product innovation & a thorough understanding of customers’ needs & objectives keep Spiroflow at the forefront of the industry. Spiroflow Systems offers flexible screw, aero mechanical, pneumatic, tubular cable & chain drag conveyors as well as bulk...

For over 40 years, CDM’s mission has been to use our excellent application knowledge and customer service to provide our clients with superior solutions. We have grown to become a world leader in the manufacturing of conveying systems, conveyor chains, and material handling equipment. Industries we serve include minerals and mining, pulp and paper, and potash and fertilizer. Contact us today...

At Syntron Material Handling, we pride ourselves on our innovative screw machine products that redefine efficiency and reliability in material handling solutions. With years of expertise and dedication to excellence, we offer a comprehensive range of screw machines designed to meet the diverse needs of industries worldwide.

More Auger Conveyor Manufacturers

As a productive technique to carry semi-solid items in modern industry, auger conveyors are frequently employed horizontally or at a slight downwards inclination. However, it is possible to use screw conveyors with the material flow slanted upward. This is a cost-effective way to elevate and express where there is room.

Types of Auger Conveyors

Horizontal Screw Conveyors

The most basic type of screw conveyor is a horizontal one. This arrangement can accommodate numerous bulk material properties. In addition, through the use of numerous inlets and discharge points, they can distribute the bulk materials to different parts of the screw conveyor in an efficient manner. Compared to conventional belt conveyors, horizontal auger conveyors are affordable alternatives that work well with free-flowing and non-flowing media. They are also excellent for homogenizing mixtures and, depending on the setting, can either be completely enclosed or left open for examination.

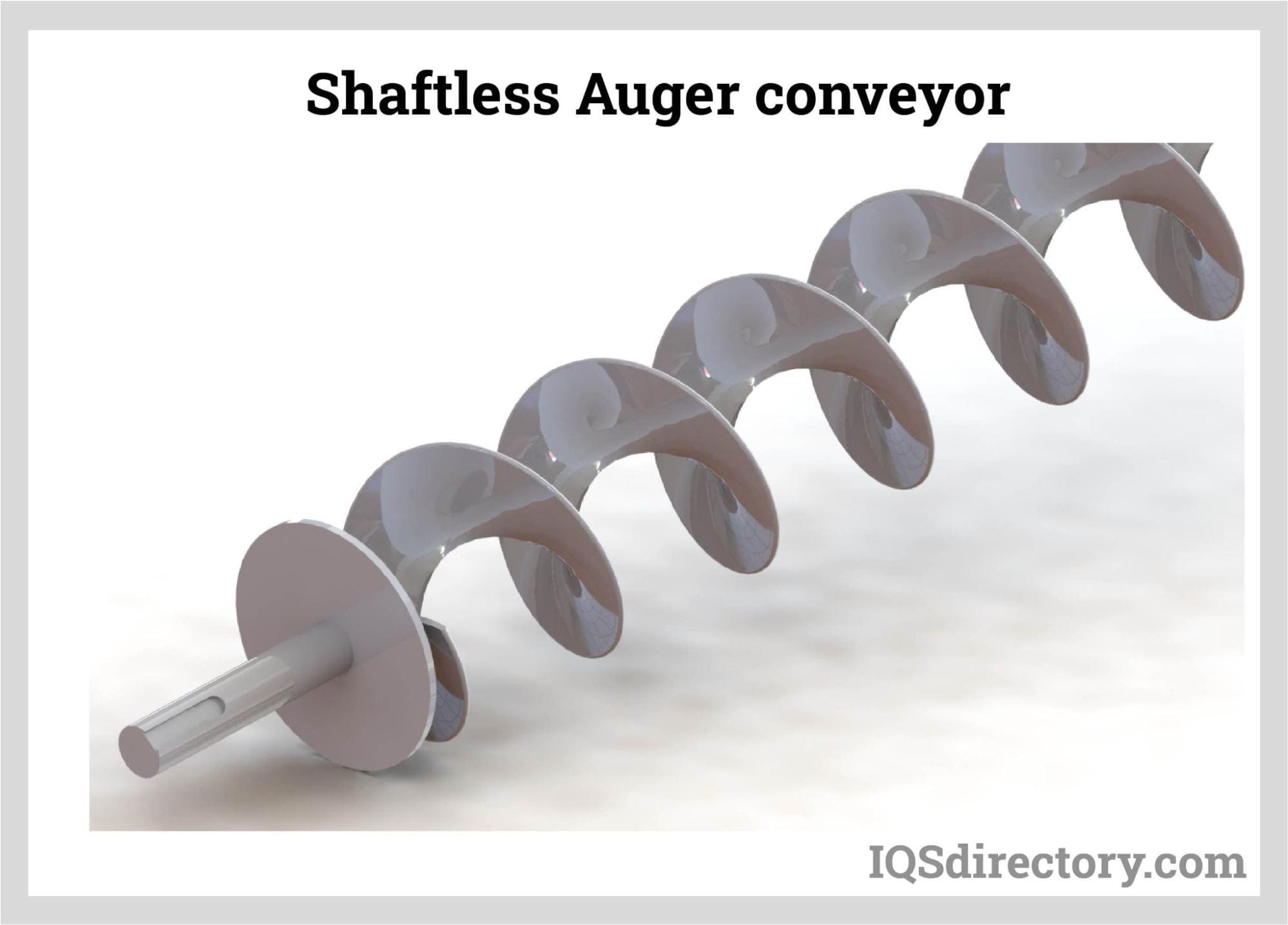

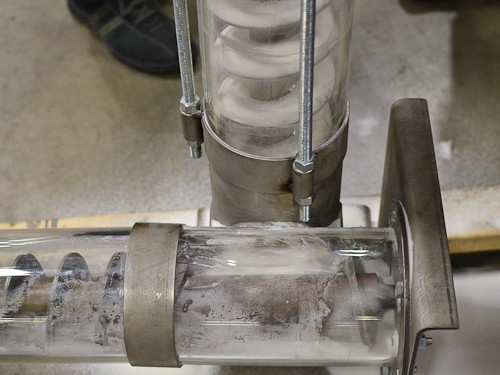

Shaftless Auger Conveyor

A shaftless auger conveyor, often referred to as a ribbon screw conveyor, is an enhancement over the conventional screw design since it enables the material to flow "through" the drill and around it. Due to the improvement in conveyable products' efficiency, flexibility, complexity, and range, this seemingly insignificant modification has a significant practical impact. They may move commodities not generally handled by screw conveyors, such as highly damp or non-flowing goods, and are essentially non-clogging.

Higher filling rates and lower RPMs are made possible by the shaftless spiral of a shaftless conveyor, which means less wear and fewer maintenance requirements or downtimes. Manufacturers can use numerous materials to create spirals.

Shaftless spiral conveyors are made to move materials that are hard to handle, including grit, industrial sludges, sticky, viscous, and stringy materials, dewatered municipal sludge, and wastewater screens. They are most frequently found in wastewater treatment, mining, food and chemical processing, and other crucial industries. Screw conveyors without shafts simplify and increase the efficiency of conveying.

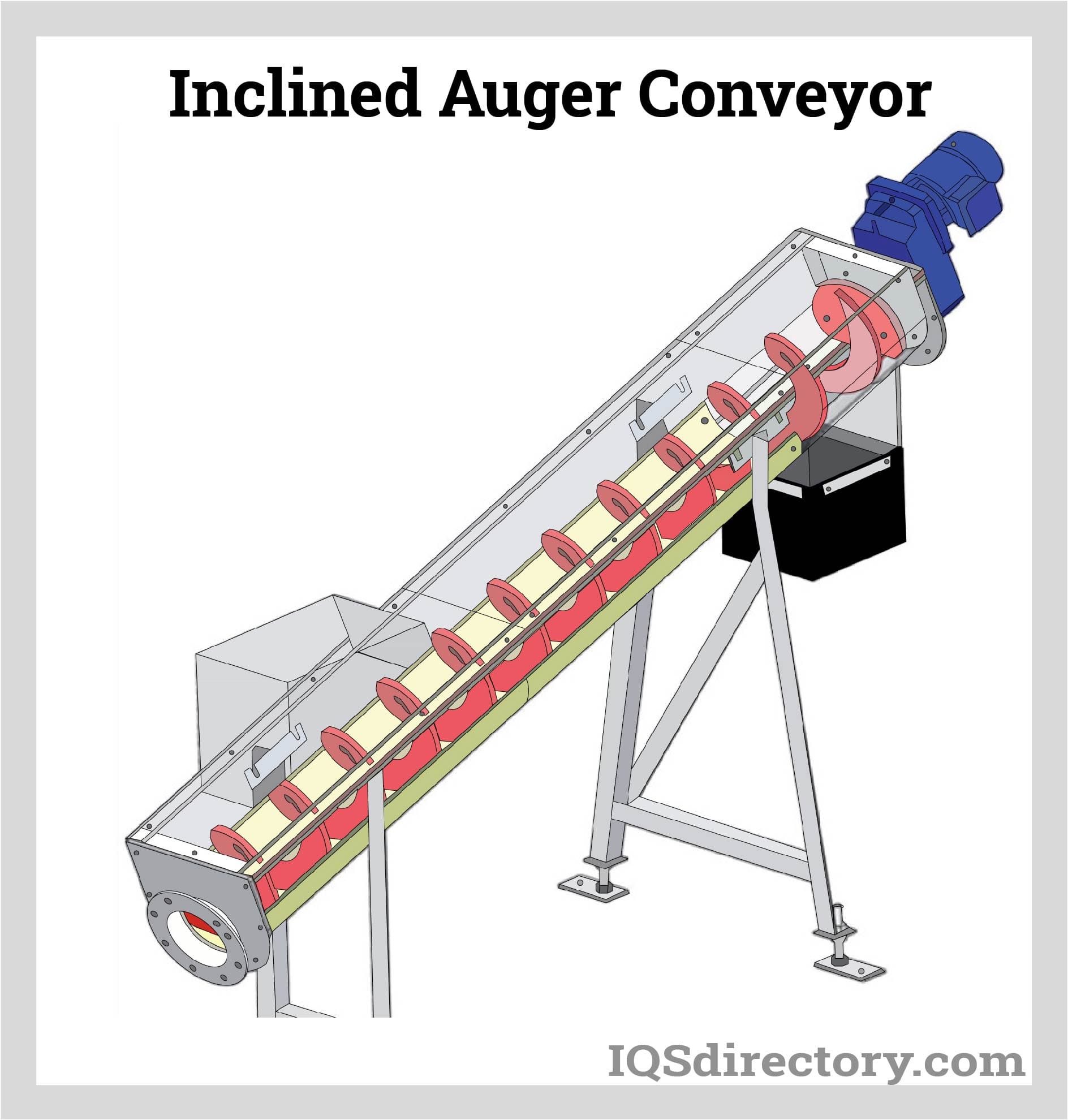

Inclined Auger Conveyor

Similar in function to most augers, inclined screw conveyors are utilized at an angle of inclination between 0 and 45 degrees. Due to the gravitational attraction and fallback of the bulk material, the efficiency and load capacity of the auger conveyor diminish as the angle of inclination increases while the power required increases. Utilizing a decreased pitch conveyor, for example, one-half or two-thirds of the screw diameter improves the conveying surface and lessens material fallback to offset the detrimental impacts of inclination. Utilizing tubular troughs lessens material fallback as well.

Manufacturers must build the conveyor more carefully since more torque is needed to pull the product through it. To enhance effectiveness and lower the demand for additional effort, the angle of incline should be as small as possible.

Applications of Auger Conveyors

- Snow can be moved by the auger conveyer in snowblowers so that it can be flung into the discharge chute by an impeller.

- To transfer the unthreshed crop into the threshing mechanism and combine harvesters use both enclosed and open augers to carry harvest into the machine's hopper.

- Ice resurfacers use augers to scrape off loose ice fragments from the ice's surface.

- In some garbage compactors, the garbage is pushed into a lowered plate at one end using a drill.

- Additionally, food ingredients are pushed through dies to create pellets using augers. These undergo additional processing to create goods like bran flakes.

- In oil fields, augers also move rock shavings to skips and away from shakers.

- Additionally, some pellet stoves and grills use augers to transfer fuel from a storage hopper into the firebox controllably.

- Auger conveyors are frequently used in wastewater treatment facilities to remove solid debris from the treatment process.

Benefits of Auger Conveyors

- Augers are capable of handling various materials. In the industrial setting, moist, sluggish, and sticky materials are transported using a customized auger conveyor manufactured without a center pipe.

- Multiple inlets and outflow sites are possible with auger conveyors. Bulk supplies can be transported and dispersed as needed to different places. Slide gates or valves can be added to an auger conveyor to regulate the flow in and out.

- Auger conveyors are incredibly small and adaptable to crowded spaces. Unlike a belt or drag conveyor, a screw conveyor does not have a return.

- Auger conveyors are simple to set up and offer more security while working at a higher elevation.

- Auger conveyors can break up big lumps and mix different materials.

- Products can be heated, cooled, or dried down an auger conveyor. An auger conveyor can be jacketed or use a hollow-flight design to provide the required heat transmission for the application, depending on the need for heat transfer.

- The internal pressure and vapor can be retained using auger conveyors; this is crucial to remember when handling harmful or dangerous products.

- Auger conveyors may provide an airlock between upstream and downstream equipment.

Choosing the Right Auger Conveyor Manufacturer

To make sure you have the most productive outcome when purchasing an auger conveyor from an auger conveyor manufacturer, it is important to compare at least 4 companies using our list of auger conveyor companies. Each auger conveyor manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each auger conveyor company website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple auger conveyor companies with the same form.

Bulk Bag Handling

Bulk Bag Handling Industrial Dryers

Industrial Dryers Mixers & Blenders

Mixers & Blenders Palletizers

Palletizers Pneumatic Conveyors

Pneumatic Conveyors Screw Conveyors

Screw Conveyors Vibratory Feeders

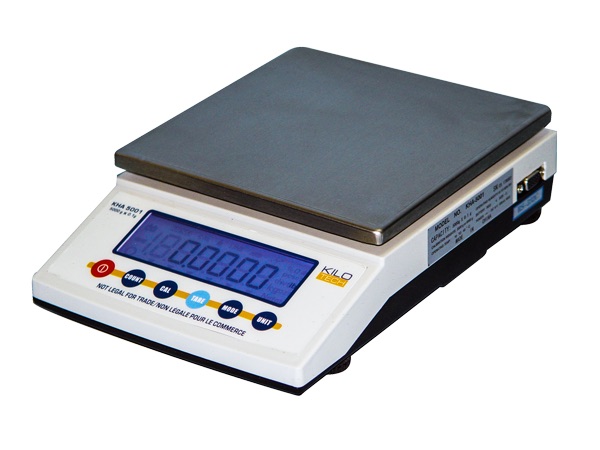

Vibratory Feeders Weighing Systems & Scales

Weighing Systems & Scales Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services