A screw conveyor is a volumetric conveying equipment. A fixed volume of the material is discharged with each turn of the screw flight. A screw conveyor is used to move product from one location to another, which is always managed by having another conveyor or measuring equipment feed into the entrance. Read More…

We are a US based, family owned company specializing in the design and manufacturing of screw conveyors in all configurations: vertical, inclined, shaftless, live bottom, plug screws, feeders, mixers, heating/cooling, FDA/USDA approved, screw presses and more.

Automated Flexible Conveyor (AFC) designs and manufactures the SPIRALFEEDER(TM) flexible screw conveyors to automatically transfer, load, weigh, and unload powders, pellets, granules, mixtures, and other dry, bulk materials fast, gently, and safely. Expert engineers offer decades of experience in designing the ideal custom screw conveyor for your bulk material handling application. Try your...

ISC Manufacturing LLC has specialized in screw conveyor manufacturing since 1976. Experts in the field of CNC machining, ISC designs & manufactures custom feeders, mixing & drag conveyors, bucket elevators, ribbon & paddle mixers, chutes & more. Our screw conveyor technology is such that our conveyors are capable of conveying, feeding, elevating & mixing. Ask about our service repair center!

At Akona Process Solutions, we take pride in engineering screw conveyors that provide reliable and efficient material handling for a wide range of industries. We design our conveyors to move bulk materials with precision, ensuring smooth and consistent flow whether the application involves powders, granules, or heavier solids.

At ProcessBarron, we specialize in delivering engineered material handling solutions that keep industrial operations moving efficiently and reliably. Our expertise in screw conveyors allows us to design and manufacture equipment that handles a wide range of bulk materials with precision and durability.

At Screw Conveyor Parts, LLC, we take pride in being a trusted resource for everything related to screw conveyors. We offer a comprehensive selection of screw conveyor components and systems designed to meet the demands of a wide range of industries, including agriculture, food processing, wastewater treatment, and manufacturing.

More Screw Conveyor Design Manufacturers

Screw Conveyor Design: Principles, Applications, and Best Practices

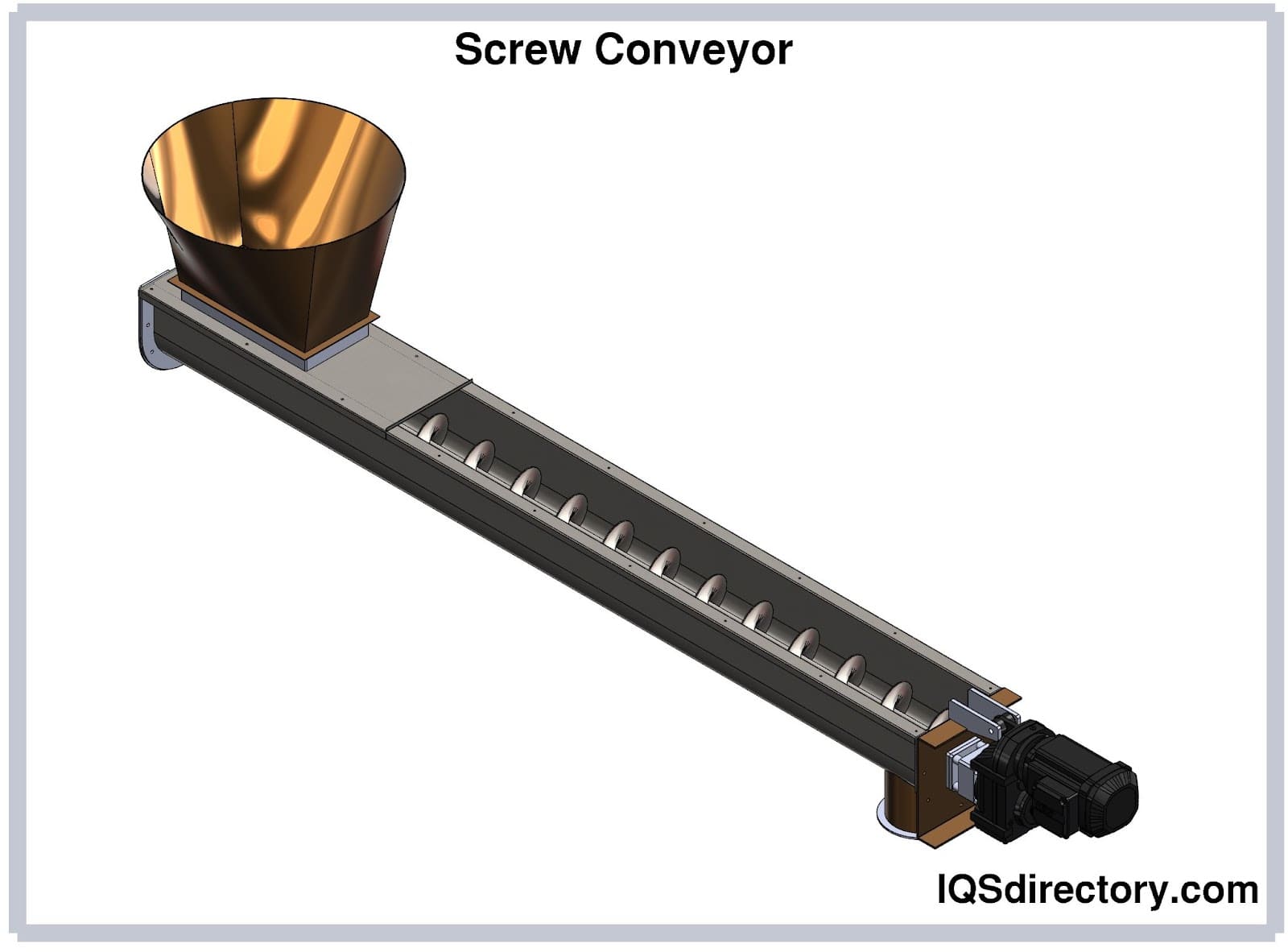

The intake of a screw conveyor is generally connected to rotary valves, other conveyors, screw feeders, or even additional screw conveyors. This essential equipment is widely utilized in bulk material handling systems across industries such as agriculture, food processing, mining, chemicals, and manufacturing. Whether you need to move powders, granules, or granular solids, a well-designed screw conveyor system can provide a reliable, efficient, and cost-effective solution for your material transport needs.

Like screw conveyors, screw feeders or feeders are constantly flood-loaded or full in the entering section, ensuring consistent feed rates and smooth material flow. These systems are especially valuable for processes that require precise batching, controlled discharge, or regulated feeding into downstream equipment such as mixers, crushers, or packaging lines.

What is a Screw Conveyor? Understanding the Basics

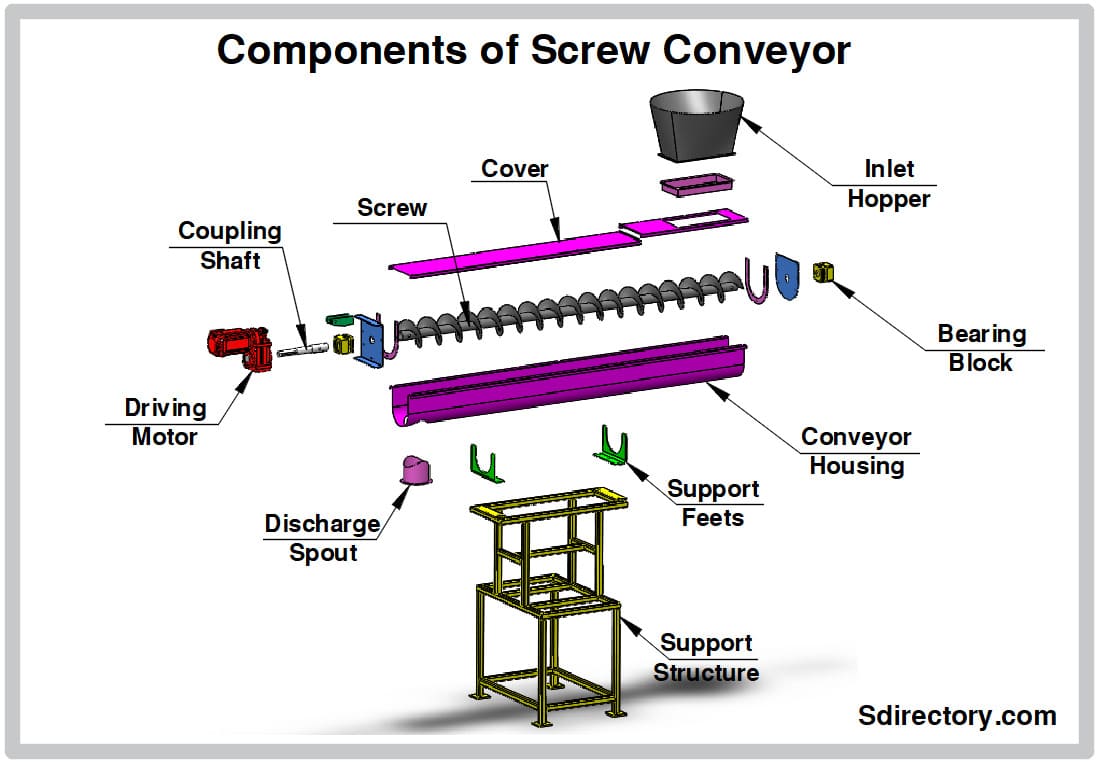

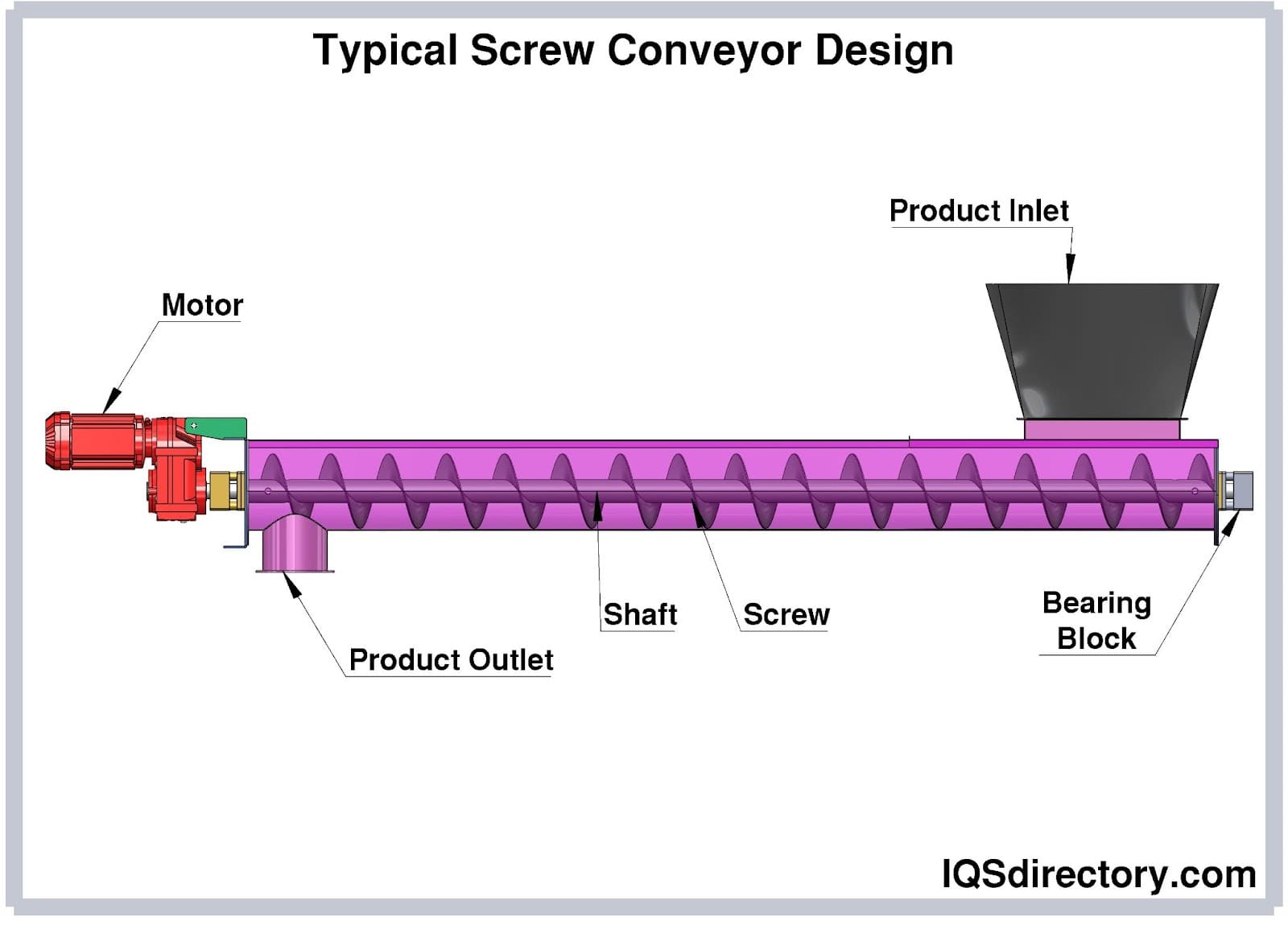

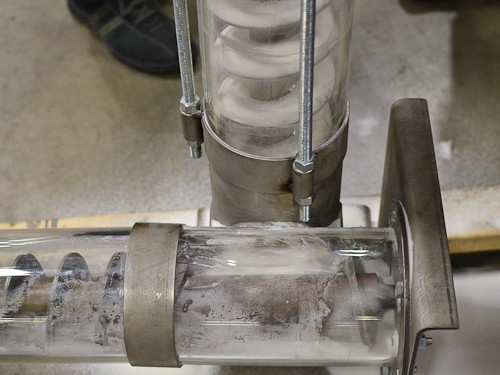

A screw conveyor (sometimes called an auger conveyor or helical conveyor) is a mechanical device that uses a rotating helical screw blade, typically within a U-shaped trough or tubular casing, to move bulk materials along a defined path. Screw conveyors are highly adaptable and can be configured for horizontal, inclined, or even vertical movement of materials. They are a cornerstone technology in bulk solids handling, supporting applications like waste removal, product dosing, ingredient blending, and more.

Key Applications and Use Cases for Screw Conveyors

- Food Processing: Transporting flour, grains, sugar, or other food-grade powders and ingredients between silos, mixers, and packaging lines.

- Mining & Minerals: Conveying abrasive minerals, ores, sand, and gravel in mining operations, often with abrasion-resistant materials.

- Agriculture: Moving animal feed, grain, seed, or fertilizer in bulk storage and transfer systems.

- Chemicals: Handling powdered chemicals, resins, and additives in controlled environments where dust containment may be critical.

- Wastewater Treatment: Removing sludge, grit, or dewatered solids from process streams.

- Manufacturing: Feeding plastic pellets, chips, or regrind into extruders, molds, or granulators.

Wondering if a screw conveyor is right for your process? Ask yourself: What material am I conveying? What throughput do I need? Are there any sanitary, abrasive, or hazardous requirements?

Factors Influencing Screw Conveyor Design

The Material Classification Code Chart lists typical characteristics of the granular particles to be transported, such as abrasiveness, corrosiveness, density, particle size, and flowability. To select the best machinery for your intended purpose, it is crucial to understand and carefully examine these characteristics when designing screw conveyors. The right design ensures optimal material handling efficiency, minimizes wear, and reduces maintenance costs.

Abrasive Particulates

When carrying abrasive grains or minerals, screw conveyor components may experience extreme wear and strain. As a result, various screw conveyor design types and materials—such as hardened steel, abrasion-resistant alloys, or special coatings—are best suited for abrasion resistance. Selecting the correct screw material and trough liner can greatly extend the life of your equipment in harsh applications.

The trough of the screw conveyor can accumulate and harden certain transporting materials, especially sticky or cohesive substances. These materials also have the propensity to absorb moisture and pack tightly, leading to potential blockages or build-up. The ability to prevent build-up incidents in the trough is improved by designing a closer gap between the trough and the screw. Additionally, a high screw conveyor torque is required to cut through hardened or compacted particles, a critical consideration in screw conveyor sizing and motor selection.

Generation of Static Electricity

Static electricity can be produced throughout the conveying process as the screw augers rotate and agitate bulk materials, especially with dry powders or plastics. To minimize the risk of static discharge, best practices include grounding the screw conveyor's trough at multiple points. Reducing trough loading and operating the screw conveyor at lower speeds can also lower static buildup.

Flammability and Safety Considerations

Flammable and explosive materials can ignite whenever oxygen and ignition sources are present. To enhance safety, screw conveyors handling such materials should be constructed of non-sparking materials (such as stainless steel or aluminum alloys), and feature tight troughs or housings with shaft seals to keep oxygen out. Some systems are designed to operate under inert atmospheres, such as nitrogen purging, to further reduce fire and explosion risk.

Additional design considerations include:

- Explosion-proof motors

- Specialized controls or monitoring sensors

- Emergency shutoff devices

- Compliance with ATEX, OSHA, or NFPA safety standards

Bulk Material Properties and Their Impact on Design

The following properties of the transported bulk material directly determine the design of the conveyor size, speed, and horsepower requirements:

- Maximum particle size: Larger particles may require bigger screw diameters or custom flights to prevent clogging.

- Bulk density: Heavier materials require more power and a stronger screw shaft.

- Trough loading: The percentage of the trough cross-section filled with material; affects throughput and risk of spillage.

- Material factor: Includes abrasiveness, flowability, and tendency to cake, which impact flight design and liner selection.

Screw Conveyor Design: Step-by-Step Guide

To design a screw feeder or conveyor for your application, you must first know the required capacity and the properties of the material to be handled. The screw size, pitch, speed, and material selection are then determined based on those requirements. This process is essential for ensuring reliable and efficient bulk material handling in any industrial or commercial setting.

How to Calculate Screw Conveyor Capacity

The following formula can be used to estimate the capacity of a screw conveyor with a standard screw flight:

Q = 60 × π⁄4 × D2 × S × N × α × ρ × C

Where:

- Q = Screw Capacity in kg/h

- D = Screw Diameter in meters (m)

- S = Screw Pitch in meters (m)

- N = Screw speed in revolutions per minute (rpm)

- α = Loading ratio (fraction of cross-section filled)

- ρ = Material loose density in kg/m3

- C = Inclination correction factor (accounts for sloped conveyors)

Step 1: Define Your Requirements

- Clearly specify the required capacity (kg/h or tons/h), desired throughput, and the type of material to be conveyed.

- Identify environmental factors (temperature, humidity, explosion risk) and sanitary or regulatory requirements.

- The screw design must have a capacity equal to or greater than this figure to ensure system reliability and avoid bottlenecks.

Step 2: Calculate Conveyor Capacity

- Assume a screw diameter (D) based on initial material flow and space constraints.

- Define the screw pitch based on the diameter of the screw:

- Estimate the loading ratio based on the characteristics of the material:

- Loading ratios may be higher or lower than average; in extreme cases, the ratio may exceed 95%. Adjust calculations based on actual material tests or supplier recommendations.

| Pitch | Pitch Length S |

|---|---|

| Standard | S = D |

| Short | S = 2/3 × D |

| Half | S = D/2 |

| Long | S = 1.5 × D |

| Material | Min Loading Ratio | Max Loading Ratio |

|---|---|---|

| Not free-flowing | 0.12 | 0.15 |

| Average flowability | 0.25 | 0.30 |

| Free-flowing | 0.4 | 0.45 |

Step 3: Compare Calculated Capacity to Maximum Screw Speed

Reference the table below for typical maximum screw speeds by diameter and trough loading:

| Screw Diameter (m) | 15% Loading | 30%A | 30%B | 45% Loading |

|---|---|---|---|---|

| 0.1 | 69 | 139 | 69 | 190 |

| 0.15 | 66 | 132 | 66 | 182 |

| 0.23 | 62 | 122 | 62 | 170 |

| 0.25 | 60 | 118 | 60 | 165 |

| 0.30 | 58 | 111 | 58 | 157 |

| 0.36 | 56 | 104 | 56 | 148 |

| 0.41 | 53 | 97 | 53 | 140 |

| 0.46 | 50 | 90 | 50 | 131 |

| 0.51 | 47 | 82 | 47 | 122 |

If the calculated speed at Step 2 is less than the maximum speed for your chosen screw diameter, the design is acceptable. If it exceeds the max speed, adjust a key parameter (typically diameter or pitch) and recalculate. Need help troubleshooting screw conveyor sizing? Contact our engineering team for design assistance.

Step 4: Power Calculations and Motor Sizing

Power requirements are a crucial factor in ensuring your screw conveyor operates efficiently and reliably. The total power required (P) for a screw conveyor is calculated as follows:

P = PH + PN + PSt

- PH: Power required to move the material horizontally (main bulk movement).

- PN: Power required to operate the unloaded screw (overcoming internal friction and inertia).

- PSt: Power required for inclined screw conveyors (lifting material against gravity).

Choosing the correct gearbox, shaft, and drive system based on these calculations is vital for long-term performance and reduced downtime.

Choosing the Right Screw Conveyor for Your Application

With various screw conveyor types—including shafted, shaftless, tubular, U-trough, vertical, and flexible screw conveyors—it’s important to match the right system to your specific process requirements. Consider the following decision factors:

- Material Characteristics: Is your material abrasive, corrosive, sticky, or prone to clumping?

- Capacity & Throughput: Do you need high-volume transfer or precise metering?

- Installation Environment: Will the conveyor be exposed to washdowns, high temperatures, or corrosive chemicals?

- Sanitary Design: Does your application require food-grade or easy-to-clean construction?

- Maintenance & Accessibility: Are components easily replaceable? Is there access for cleaning and inspection?

- Integration: Will the screw conveyor connect to existing hoppers, bins, rotary valves, or other equipment?

- Budget & Total Cost of Ownership: Consider not just upfront price but also expected lifespan, maintenance needs, and energy consumption.

For a side-by-side comparison of features and options.

Benefits of a Well-Designed Screw Conveyor System

- Adaptable Configurations: Handle a wide range of materials and flow rates in horizontal, inclined, or vertical layouts.

- Sealed Construction: Minimize dust, contamination, and spillage, enhancing workplace safety and cleanliness.

- Energy Efficiency: Optimized design and motor selection reduce energy use for cost savings.

- Low Maintenance: Fewer moving parts and robust construction mean less downtime and lower lifetime costs.

- Customizable: Tailor screw size, pitch, material, liners, and drive systems to your exact process needs.

- Integration: Easily connect to feeders, hoppers, and other equipment for automated, continuous operations.

Frequently Asked Questions About Screw Conveyors

- What materials can a screw conveyor handle? Most dry bulk solids, including powders, granules, flakes, pellets, and small chips. Special designs can handle sticky, abrasive, or corrosive materials.

- How do I choose between a shafted and shaftless screw conveyor? Shaftless designs are ideal for sticky or fibrous materials, as they reduce clogging; shafted models are used for free-flowing, non-cohesive solids.

- Can screw conveyors operate on an incline? Yes, but capacity decreases as incline increases. Specialized designs and corrective factors can help optimize inclined screw conveyor performance.

- What maintenance is required? Regular inspection of bearings, seals, and drive components; periodic cleaning to prevent buildup or blockages; lubrication as needed.

Choosing the Proper Screw Conveyor Design Company

To ensure the best outcome when selecting a screw conveyor design company, it is important to compare at least four experienced providers using our screw conveyor design directory. Each company profile highlights their areas of expertise, industry certifications, and capabilities, plus a direct contact form for more information or to request a quote. Use our proprietary website previewer to see what each company specializes in, and our simple RFQ form to contact multiple screw conveyor manufacturers with a single request. This streamlined process helps buyers make well-informed decisions, compare quotes, and select the optimal partner for their bulk material handling needs.

Still have questions or need a custom screw conveyor design? Contact our engineering team for a free consultation or request a quote today. We’re here to help you achieve reliable, efficient, and cost-effective material handling in your operation.

Bulk Bag Handling

Bulk Bag Handling Industrial Dryers

Industrial Dryers Mixers & Blenders

Mixers & Blenders Palletizers

Palletizers Pneumatic Conveyors

Pneumatic Conveyors Screw Conveyors

Screw Conveyors Vibratory Feeders

Vibratory Feeders Weighing Systems & Scales

Weighing Systems & Scales Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services